Key Takeaways

- Manufacturers must rethink traditional supply chain models by leveraging AI-driven forecasting, automation, and dynamic inventory optimization to reduce costs and disruptions.

- Reshoring and nearshoring are accelerating, with nearly one-quarter of manufacturers moving operations closer to home to improve resilience and control.

- Aligning business goals with technology and data is critical for building efficient supply chains that can adapt to global challenges.

Rising costs, geopolitical tensions, and sustainability mandates have created a perfect storm for manufacturers. In 2026, supply chain challenges were cited by one-third of manufacturers as a top challenge. The message is clear: traditional supply chain models are no longer enough.

Manufacturers can no longer rely on single-source suppliers or outdated forecasting models. To thrive, you must reset your supply chain strategies.

Here's how.

AI and Automation

It’s no secret that AI has changed the game for many industries. In manufacturing, AI can help:

- Forecast consumer demand shifts due to tariffs' effects or other factors.

- Optimize production line schedules to ensure the most efficient allocation of resources.

- Monitor machine usage time and maintenance schedules to avoid downtime from broken machinery and to schedule routine maintenance.

- Identify which parts of the operation are best suited for reshoring/nearshoring.

- Improve demand planning and forecasting to reduce stockouts with the help of predictive analytics.

- Create dynamic inventory optimization.

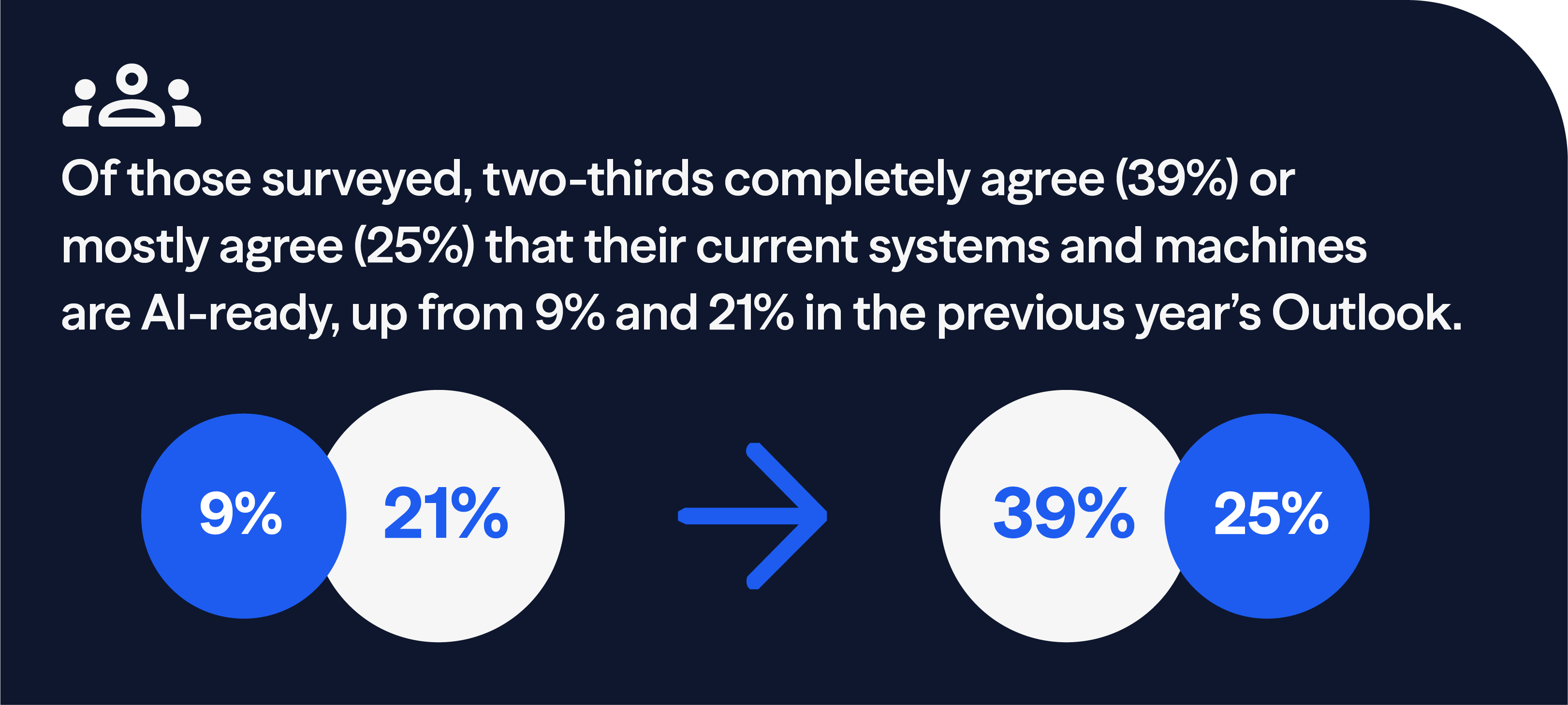

Three-fourths of manufacturers and distributors report increasing their investment in AI solutions, signaling high demand for new technology. However, AI adoption is often the most successful when companies balance innovation (exploring new AI applications) with optimization (getting more from existing systems).

Reshoring and Nearshoring

Tariff uncertainty, new tax legislation, and advancements in technology are creating a complex business environment for manufacturers and distributors. The new tax legislation alone has led to significant changes in business planning decisions, regardless of industry.

It’s no wonder that manufacturers are considering new ways to do business. In fact, 24% of manufacturers and distributors are near-shoring or reshoring production and sourcing. This is almost twice the percentage from our 2025 Outlook Report.

Before committing to reshoring, it’s important for manufacturers to think proactively — and long term — about their organization and its needs.

Things to consider include:

- What are your customers’ buying habits?

- Where is the best location for sourcing raw materials?

- How and where are your products being sourced?

- How are your products being distributed?

- How will a location change impact your organization?

Planning is key to making reshoring or nearshoring successful. When one of our clients faced sudden tariff increases, they needed to onboard a U.S. warehouse in under a month. Their real-time response was successful due to early ERP implementation, scalable systems, and rapid integration and testing that launched the warehouse in three weeks.

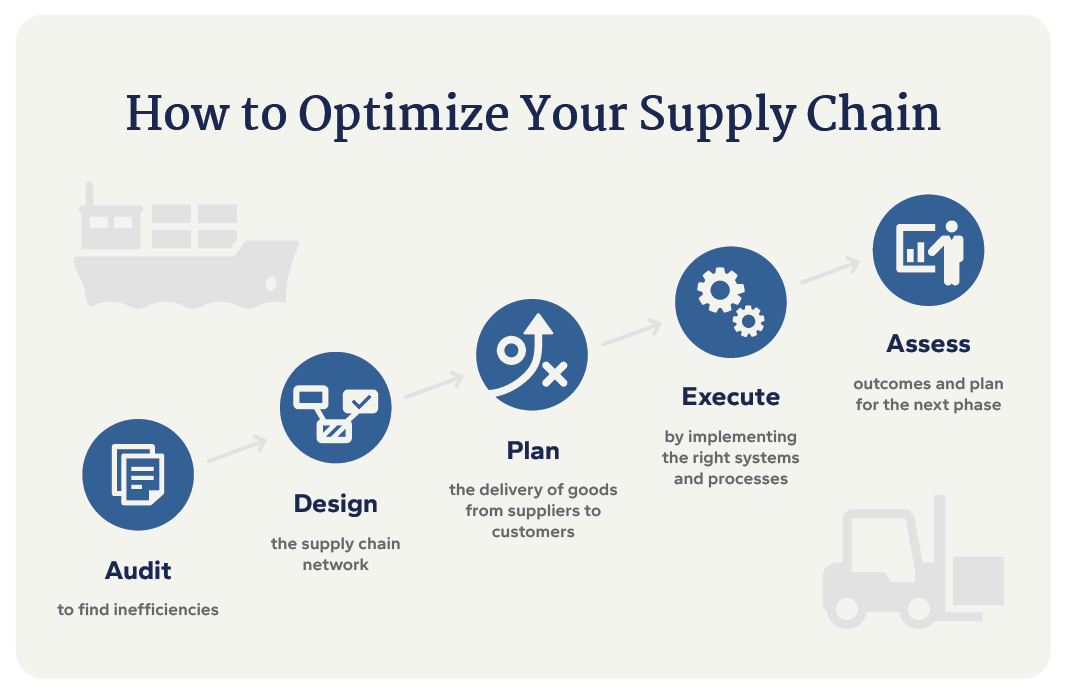

Optimize Your Supply Chain

Most manufacturers are expecting production increases in the next 12 months. With the right technology solutions, operational efficiency can drastically increase.

Specifically, mid-level manufacturers are focusing on top investment targets like:

- Inventory optimization (32%)

- Process optimization (31%)

- Predictive maintenance (30%)

But the first step in optimizing your supply chain is to align your current processes with your business goals.

Areas to review include:

- Demand planning

- Supply management

- Production management

- Inventory management

- Pricing strategy

- Event management

- Distribution planning

- Integrated business planning

Next Steps in Supply Chain Resilience

So how best to improve supply chain performance?

- 54% of manufacturers report outsourcing their operations.

- 57% report utilizing imported supplies.

- 32% of manufacturers are increasing the number of suppliers.

- 32% are utilizing more AI and machine learning for supply chain.

The strongest businesses focus on technology and goals that support how your business runs. When manufacturers align business objectives with reliable, actionable data, they create a supply chain that can adapt to changing conditions, faster.

Manufacturers face disruption — Eide Bailly provides strategies to build resilient supply chains, optimize costs, and embrace reshoring for long-term success. Let us show you how.

Looking Ahead: The Future of Supply Chain Innovation

The next era of manufacturing supply chains will be shaped by rapid advances in technology and shifting global dynamics. Key trends to watch include:

- Data and Trend Analysis: Access to real-time data is essential for improving profit margins. For instance, when considering freight choices, having reliable and precise data enables you to make well-informed decisions regarding shipping options.

- Generative AI and Autonomous Planning: Manufacturers are beginning to deploy generative AI for scenario modeling, risk analysis, and autonomous supply chain planning.

- Sustainability Tech: As ESG regulations tighten, manufacturers will invest in carbon tracking, circular supply chain models, and green logistics platforms to meet compliance and customer expectations.

- Digital Twins and IoT Expansion: Real-time digital replicas of supply chains, powered by IoT sensors, will provide unprecedented visibility and predictive capabilities, helping manufacturers anticipate and respond to challenges before they arise.

- Cybersecurity and Data Integrity: As supply chains become more digital, protecting sensitive data and ensuring system integrity will be critical for operational continuity and trust.

Ready to future-proof your supply chain and drive lasting growth?

Contact Eide Bailly Manufacturing Advisors | Access the 2026 Manufacturing Outlook Report

Frequently Asked Questions

What is reshoring?

Reshoring means bringing manufacturing back to the company’s home country for greater control and reduced risk.

How does AI improve supply chain efficiency?

AI enhances forecasting accuracy, automates workflows, and provides real-time visibility, reducing costs and disruptions.

Why is nearshoring gaining traction?

Nearshoring offers proximity benefits — lower transportation costs, faster delivery, and alignment with trade agreements.

Why choose Eide Bailly for your manufacturing needs?

Eide Bailly helps manufacturers work smarter — financially, operationally, and strategically. With over 100 years of experience and thousands of manufacturing clients served, we deliver audit, tax, technology, and advisory solutions that optimize supply chains, improve efficiency, and enable digital transformation. Our team combines industry insight with innovative tools to help manufacturers reduce risk, enhance performance, and grow with confidence.

2026 Mid-Market Manufacturing Outlook Report

Manufacturing, Distribution, and Logistics

Rely on the trusted expertise of manufacturing advisors to help you build and execute your strategic vision.

Who We Are

Eide Bailly is a CPA firm bringing practical expertise in tax, audit, and advisory to help you perform, protect, and prosper with confidence.