Key Takeaways

- The manufacturing industry has capitalized on artificial intelligence (AI) for over a century.

- The use of AI in manufacturing has evolved in a way that has transformed operations, reducing costs through automation and predictive maintenance, increasing operational efficiency, and enhancing quality control in real-time.

- A partner can help guide you in your transformation journey so you can harness the full potential of AI for your manufacturing operations.

Artificial intelligence (AI) in manufacturing isn’t a futuristic concept—it's a reality that businesses are increasingly leveraging to enhance efficiency, reduce costs, and gain a competitive edge. According to research from the Manufacturing Leadership Council, 96% of manufacturers plan to increase AI investments in operations by 2030.

The History of AI in Manufacturing

AI's historical journey in manufacturing includes remarkable milestones, such as Ford's use of electro-mechanical vision systems during World War II to inspect crucial components. This innovation allowed Ford to reduce production cycle times significantly—the Willow Run B-24 plant saw a 60% decrease in production cycle times, allowing Ford to produce a B-24 every hour.

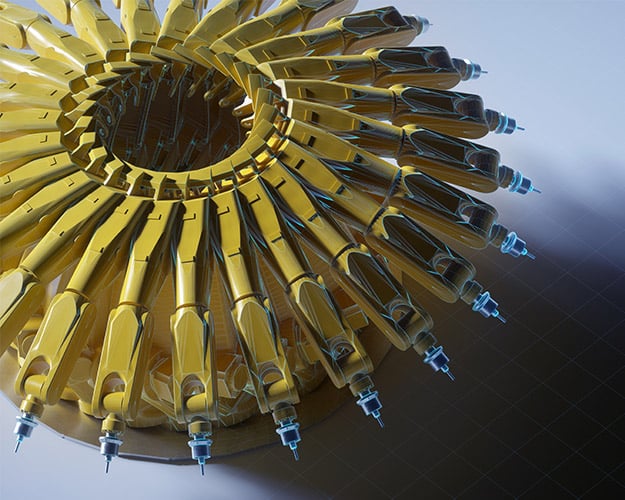

In the 1950s and 60s, robotics and more complex AI-driven processes emerged. AI-equipped robots were programmed to adapt to changing conditions, and advanced engineering concepts like Failure Modes and Effects Analysis (FMEA) and Statistical Process Control (SPC) became integral to production health analysis.

AI in Manufacturing Today

Today, AI in manufacturing has evolved to address a wide range of applications, including:

- Production Line Scheduling: AI optimizes the scheduling of production lines, ensuring efficient use of resources.

- Administrative Task Automation: Repetitive administrative tasks are automated, reducing human labor and human error.

- Predictive Maintenance: AI analyzes data to predict when machinery requires maintenance, minimizing downtime and repair costs.

- Quality Control: Real-time computer vision and machine learning detect defects, ensuring products meet high-quality standards.

- Personalized Manufacturing: AI-driven customization allows manufacturers to produce highly customized products efficiently, catering to individual customer needs.

The Power of AI Technologies

Modern AI technologies have reached unprecedented levels of sophistication. They can learn from experience and make more complex decisions thanks to advances in computing power, large-scale data integration, and more. These AI advancements have significantly transformed manufacturing by reducing costs, increasing efficiency, and improving quality and productivity.

Cost Reduction

AI-driven predictive maintenance helps prevent costly machinery breakdowns, lowering maintenance and repair expenses. Companies can realize substantial cost reductions in operational and maintenance expenses, often resulting in a more efficient cost structure.

Improved Quality and Productivity

AI technologies can enhance product quality and production efficiency through real-time quality control, predictive maintenance, and process optimization. By automating quality inspections and monitoring, manufacturers can significantly reduce defects and rework. This not only leads to higher-quality products but also boosts productivity as resources are utilized more effectively.

Enhanced Decision-Making and Efficiency

AI provides valuable insights and data-driven recommendations that enable manufacturers to make informed decisions. This includes optimizing production schedules, managing inventory levels, and responding to changing market demands more effectively. AI-driven analytics and insights lead to better decision-making, improved operational efficiency, and increased competitiveness.

The Future of AI in Manufacturing

AI, from a manufacturing standpoint, is about leveraging non-human controlled interactions. This encompasses various technologies like electro-mechanical systems, electrical relays, control boards, and analytical calculation models. Interpretive language or learning models, or generative AI, represent the more familiar face of AI. When implemented effectively, these complex programming giants can add substantial value.

For instance, when it comes to product design and prototyping, generative AI can generate and optimize design variations based on specified parameters. This not only accelerates the design process but also allows for the creation of more innovative and efficient product designs.

While there is a growing fear that generative AI will replace jobs, the majority of manufacturing leaders do not believe this is the case. In fact, one-third expect their workforce headcount to increase because of AI.

As AI continues to evolve, its applications in manufacturing are poised to expand, offering even more benefits to companies worldwide.

However, only one-third of manufacturers report that AI initiatives are part of their overall digital transformation strategy. If you need a partner to guide you on your transformative journey and help you harness the full potential of AI in manufacturing, we can help.

How to Apply AI Strategically In Your Organization

Manufacturing

Rely on the trusted expertise of manufacturing advisors to help you build and execute your strategic vision.